Negotiable

The date of payment from buyers deliver within days

Zhejiang

Long-term effective

2023-11-09 12:31

332

Company Profile

Company Profile

By certification [File Integrity]

Contact:hengxingjixie(Mr.)

Email:

Telephone:

Phone:

Area:Zhejiang

Address:Zhejiang

Website:http://www.zlstonemachine.com/ http://hengxingjixie.crlmemory.com/

Model | 4+1 Axis CNC bridge saw | Unit |

Worktable size | L3500*W2000 | mm |

Maximum cutting | L3500*W2000*H90 | mm |

Maximum chamfering | L3500*W2000*H60 | mm |

Blade diameter | 350-425 | mm |

Main motor power | 15 | kw |

Router power | 5.5 | kw |

Control center | industry computer with CNC | Â |

Driving motor | Servo motor | Â |

Router max speed | 24000 | RPM |

Total power | 28 | kw |

Suction cup lifting weight | 200 | kg |

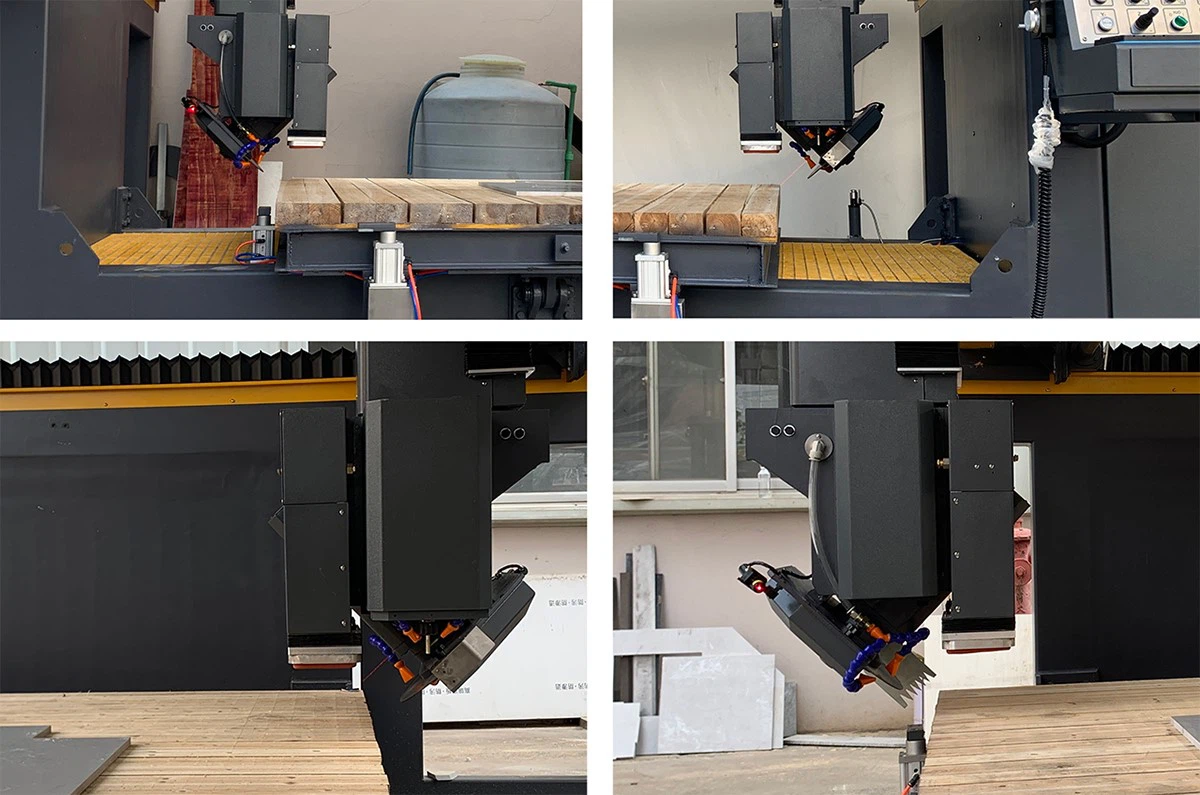

Head rotate | 0°-360° |  |

Head tilt | 0°and 45° |  |

Cylinders | 5 | group |

Dimensions | L5750*W3260*H3800 | mm |

Water consumption | 2 | m³/h |

Total weight | 5.4 | t |

Main part delivered size | 5750x2200x2500 | mm |

Machine-delivered method | Main part delivered as a whole (HQÂ container) | Â |

Â

Model | Own system (USD) | Option: ESA System | Option: Hot Galvanized (USD) | Option: front sliding doors | Option:worktable with plastic plate and rubber |

ZLBS-425CNC/4+1A | 26000 | Â | +2000 | +2000 | +1000 |

Feature

Â

1: The machine is a conjoined structure; it takes up less space and is easy to install and move.

Â

2: This machine has excellent four-side chamfering function and an excellent chamfering range 3500x2000mm

Â

​

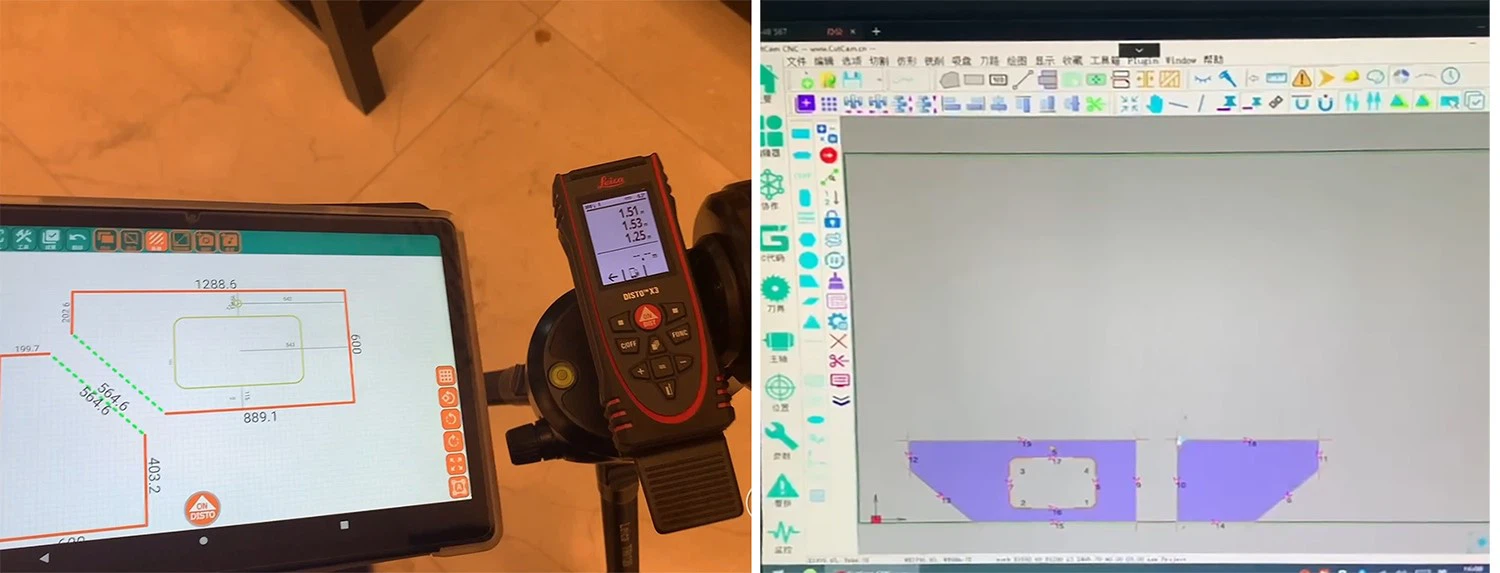

3: With an industrial computer and a 17" color touch-screen.

Â

Option: own CNC system or ESA system from Italy

4: Use a camera to locate the position of the plate and display it in the cutting procedure.

5: An automatic tool setting gauge is equipped that automatically checks the blade.

Â

6: The system has a built-in library of conventional-shaped drawings and also supports DXF format imports from a designer or a countertop measuring gauge.

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

8: The worktable can be flipped up to 85°.

9: A group of rotating cylinders on the side of the work table will automatically press the plate when the milling cutter works and automatically withdraw after the milling cutter works.

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

The operator first takes a photo of the plate and puts the layout of the drawing on the plate in the photo,then starts processing. The 4+1 Axis CNC Bridge Saw is also used to cut and chamfer conventional cross and straight slices of plates, various polygons, circles, ovals, maws, L-shaped countertops, four-sided under-hung countertops, etc. When the machine starts working, the program automatically generates the sequence and paths. Before the milling cutter works, the program will first control the cylinder to press the plate.The milling cutter can process basin holes, faucet holes, and milling inner angles.After the milling cutter is finished, the cylinder is automatically withdrawn. When the knife path overlaps. The vacuum can assist in separating the plates.It’s powerful and suitable for marble, quartz stone, granite, ceramic, sintered stone, and other types of plate-cutting processing. The machine supports downloading the measuring instrument file, then setting the drawing, and finally processing. So the machine is used to achieve dust-free installation of countertops. It is the best choice for the countertop industry.Our plant boasts a rich history of 30 top-of-the-line production machines and has been a global force in equipment manufacturing for over 15 years. Our machines are in demand across continents and are shipped to nations spanning Europe, the United States, Canada, South America, India, and Australia. As a result of the advancements in Internet technology, we can now deliver even better services to our customers remotely, strengthening our commitment to their satisfaction.

Â

The CNC bridge saw is a powerful and highly efficient technological innovation that has taken the stone-cutting industry to new heights. This amazing machine uses state-of-the-art technology to deliver precision cuts with speed and accuracy. There are several advantages associated with owning and operating a CNC bridge saw.

Â

Firstly, CNC bridge saws are incredibly versatile. They can cut through a wide variety of materials, including granite, marble, quartz, and porcelain tiles. The machine uses a diamond blade to cut through these materials with great accuracy, ensuring that each cut is clean and precise. This makes it perfect for creating custom designs and intricate patterns.

Â

Another advantage of a CNC bridge saw is its exceptional accuracy and precision. The machine is equipped with a computer control system that ensures that each cut is precisely executed. This reduces the chances of errors and ensures that the final product is of the highest quality.

Â

CNC bridge saws are also equipped with a range of safety features, making them safe to use. These features include emergency stop buttons, interlocks, and guards that prevent accidents and injuries. This makes it a safe and reliable tool for any workshop or factory.

Â

In addition to all these benefits, CNC bridge saws also help to save time and labor costs. They are highly automated, which means that they can operate in a continuous manner without the need for constant human supervision. This increases productivity and reduces labor costs, making them a smart investment for any business.

Â

Overall, a CNC bridge saw is an innovative and reliable tool that offers many benefits to businesses that want to stay competitive in the stone-cutting industry. With its exceptional accuracy, versatility, and efficiency, it is the perfect tool for any stone-cutting project.

http://www.zlstonemachine.com/